The Montréal-based food tech startup is greening one of North America’s most monopolistic and unsustainable industries with its fully autonomous microfactories.

A single spark can start a fire. Sometimes, to disrupt a market on a large scale, you have to start with a niche. For Montréal startup Relocalize, that means ice cubes—a product practically everyone uses, but few pay much attention to.

As it turns out, many of us have been consuming substandard, unsustainable ice for decades. The ice industry has long suffered from a lack of competition, or what Relocalize CEO and CFO Wayne McIntyre calls, “geographic monopolies” that discourage innovation. This persists because ice is typically transported by large networks of trucks, which create a barrier to entry.

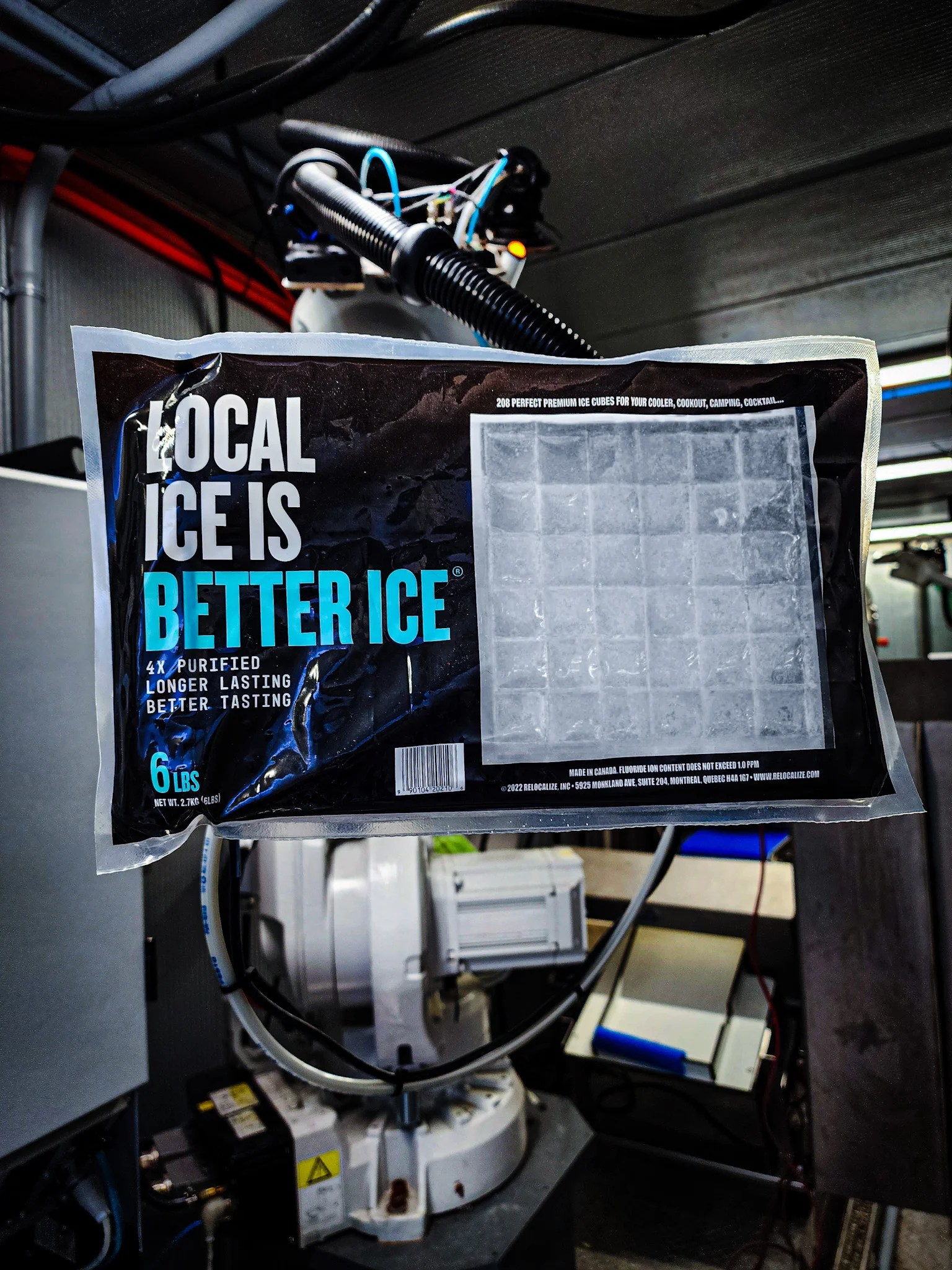

But Relocalize cuts trucks out of the equation. Instead, the food tech company creates autonomous food and beverage microfactories that allow retailers to create their own ice on site that’s higher quality, more economical, and more sustainable than traditional ice.

“Because Relocalize eliminates middle-mile transportation, we’re not dependent on trucks,” says McIntyre. “So now we can enter those markets and not be subject to the same constraints as industry incumbents. That’s why we can disrupt. We’re trying to get rid of trucks; they need trucks.”

Adventures in vertical farming

Relocalize initially began as a vertical farming concept, driven by McIntyre’s interest in sustainability and decarbonization. However, until that point, both had been more personal interests than professional ones. “At that stage in my career, I wanted to bring together the personal and professional: my passion for startups and technology as well as my passion for dealing with the reality of our climate crisis,” he says.

While McIntyre explored vertical farming, he quickly discovered that “vertical farming is really hard.” Specifically, “it’s hard to make the economics work and, even if you look at the big players in the market, it’s about a 300 per cent premium for a consumer to buy a local, high-tech vertical farm product versus regular, let’s say, lettuce.”

Realizing the fruits of vertical farming weren’t something a regular person could afford, McIntyre and his co-founder, Graham Campbell, searched for something they could do that was both “good for the planet and good for business.”

Ice, along with other products made of water, emerged as a clear opportunity to disrupt an unsustainable industry and get the economics right while doing so. “The key to rapidly scaling green solutions is combining those two elements,” says McIntyre.

Wayne McIntyre, CEO, Relocalize

Better ice is possible

Relocalize’s pitch is about more than just the environment; it’s also about quality ice. While ice is often an afterthought for consumers, McIntyre says it can be so much better than what’s typically sold at grocery and convenience stores.

“The majority of consumers today want sustainable products. At the same time, the majority of consumers want great products. So our focus has been on doing both,” he says.

“The majority of consumers want sustainable products. At the same time, the majority of consumers want great products. So our focus has been on doing both.”

“If you think of your regular bag of ice, it’s a plastic bag full of rocks of smashed up ice, often stuck together, and it doesn’t look anything like the ice in Super Bowl commercials. Well, our patented ice-making process delivers that same cube you see in those commercials, and we’re doing it with up to 90% less carbon dioxide from transportation, doing it with local water, and not wasting any water.”

Relocalize markets their ice cubes, which are purified four times, as both better tasting and longer lasting than those of the big players. They’ll also always be the perfect one-by-one inches for shaking or stirring in a drink.

From retailers’ perspective, using on-site microfactories ensures they’ll never run out of ice, which can cause major damage to their bottom line. “Ice is a surprisingly important product for convenience and grocery retailers. Many large retailers have told us right from the senior executive level that when customers go for ice, and it’s not there, they consider that a loss of long term customer value,” says McIntyre.

Much like every other industry post-COVID, supply chain challenges have impacted the ice market and deliveries are both less reliable and more expensive than ever. At the same time, retailers are looking for increased sustainability from suppliers, but having a hard time getting it from unmotivated monopolies.

As a further bonus, having on-demand ice production means stores don’t have to spend as much space, energy, or, ultimately, money on cold storage for truckloads of products.

“Whether it’s from a consumer or retailer perspective, what we brought to the market is so unique and disruptive that it’s essentially a no-brainer,” says McIntyre.

The path to fully autonomous

Relocalize’s microfactories don’t require any additional human labour. Instead, they’re entirely run by robotics. The startup’s first proof of concept is currently operational in Jacksonville, Florida, with another one to come in Canada within the next nine months.

“This was a pretty major undertaking,” says McIntyre. “We’re fortunate to have a CTO who’s a leading expert from the automotive industry, and who could really both touch all the different parts of an autonomous system and innovate across the whole technology stack.”

He says that while, generally speaking, the food industry is behind many others when it comes to autonomous production, “not only did we go where the automotive industry is, but we went to the next level where it’s actually fully autonomous and we don’t have any workers at all on site.”

To build their autonomous system, Relocalize took components from other existing systems and through “combinatorial innovation,” reworked them together into something completely new.

For other startups interested in exploring automation, McIntyre says it’s all about finding and hiring the right people with multi-disciplinary expertise, “My first tip would be that you need someone who really truly has lived all the different aspects of automation. So integration of automation, understands the software side, understands the control systems, and understands the hardware. Finding someone with that breadth of experience is really hard.”

Inside Relocalize’s fully autonomous micro-factory.

Going certified plastic negative

Relocalize walks the talk when it comes to sustainability: the startup is proudly certified plastic negative and uses plastic offsetting. However, they’re also aware of and willing to openly discuss the limitations of their green efforts. “We use a recycle-ready material that’s recyclable. However, in reality, most plastics aren’t being recycled in many jurisdictions, and we’re aware of that. That keeps us up at night,” says McIntyre. “We don’t believe in greenwashing or putting on rose-coloured glasses.”

Relocalize sees plastic offsetting as a stop-gap measure for the current moment. They hope long term, hyper localized packaging will make it easier to create plastic-free or fully circular packaging solutions. “There’s good, and then there’s perfect. But we’re not going to let perfect be the enemy of good right now,” he says.

“You can buy offsets and credits on exchanges, but knowing a project is real and being able to visit it is important.”

As other companies look to improve their eco cred, McIntyre says it’s most important to be hands-on throughout the process. “Offsetting is imperfect because sometimes it’s hard to trace it back to projects or funding. What I like about our approach is we trace our offsets to specific projects in specific places,” he says. “It’s a real project that I can hop on a plane and visit. You can buy offsets and credits on exchanges, but knowing a project is real and being able to visit it is important, so that it’s more than just a financial transaction.”

The case for productive urgency

Relocalize’s company culture is based around the ethos of productive urgency. The approach attempts to embrace the quick cycles and unexpected hurdles inherent to startup life without creating unnecessary stress for employees. “The challenge is how do you create urgency without causing stress and an organization?,” asks McIntyre.

He says too many startups get caught up in a culture of urgency for urgency’s sake, but “urgency without purpose isn’t valuable.” Not everything can be urgent, all the time.

In practice, this means not creating artificial deadlines for the sake of deadlines and carefully choosing priorities rather than attempting to make all projects a priority.

When it comes to leadership, McIntyre says he tries to adhere to productive urgency by asking himself whether any new initiative should really be handled internally, or whether it can be handled by partners or even outsourced. “It’s also saying no to things because, if not everything can be urgent, then which of the things are we just not going to do so we can focus on the urgent and important?”

One of Relocalize’s partners is RBCx, a relationship which he says helps relieve some of the financial stresses of being a scaling tech business. “A startup lives and dies on its financing partners, so if you can find somebody who actually understands your business, knows what you’re going through, and knows how to give value-add advice, that’s key. RBCx is really unique in that they truly understand the startup journey.”

To learn more about Relocalize, visit Relocalize.com.

RBCx backs some of Canada’s most daring tech companies and idea generators. We turn our experience, networks, and capital into your competitive advantage to help drive lasting change. Speak with a RBCx Technology Advisor to learn more about how we can help your business grow.

This article offers general information only and is not intended as legal, financial or other professional advice. A professional advisor should be consulted regarding your specific situation. While the information presented is believed to be factual and current, its accuracy is not guaranteed and it should not be regarded as a complete analysis of the subjects discussed. All expressions of opinion reflect the judgment of the author(s) as of the date of publication and are subject to change. No endorsement of any third parties or their advice, opinions, information, products or services is expressly given or implied by Royal Bank of Canada or its affiliates